Customer Background

A large iron and steel group with an annual output of 12 million tons of special steel production base, its #2 blast furnace is subject to long-term high temperature molten iron scouring and alkaline slag erosion, and the throat part of the furnace appears to be partially spalled, and the fluctuation of the furnace temperature leads to the decline of production efficiency.

Technical pain points

1. Conventional refractory brick masonry has a lot of joints and is prone to leakage defects

2. Maintenance cycle takes more than 15 days, which affects the continuous production

3. Temperature gradient inside the furnace varies a lot (1200-1600 ℃)

4. It needs to withstand the chemical erosion of CO gas and slag

Solution

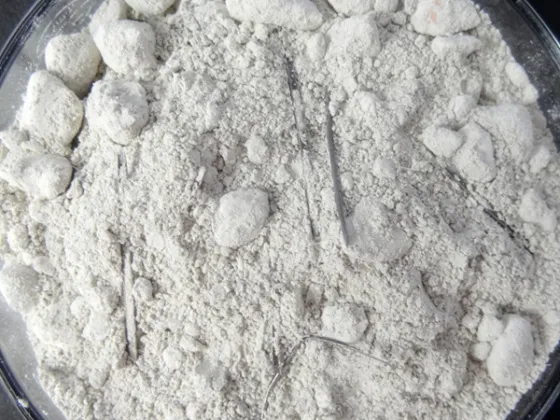

Adopting ASC-90 low-cemented corundum refractory castable researched and developed by our company

▶ Characteristics of the material:

Al₂O₃content ≥ 90%, Cr₂O₃ content ≥ 90%. Cr₂O₃ composite micropowder enhanced slag resistance

1700℃ high temperature flexural strength ≥8MPa

Thermal shock stability (1100℃ water cooling) >30 times

Bulk density 2.95g/cm³, apparent porosity ≤18%

Construction process

1. Surface treatment: Mechanical cleaning of the old lining to the structural layer, reserving anchoring nails

2. Formwork installation: Adoption of a removable steel mold, precise control of the casting thickness (150±5mm) 3. Pouring construction:

dry mixing for 3 minutes → adding 5.5% special binding agent wet mixing for 8 minutes

vibration pouring in layers, the thickness of each layer is ≤300mm

set up 8 φ20mm venting holes

4. Maintenance and baking:

natural maintenance for 24 hours → gradient heating to 600℃ at 50℃/h → soaking for 12 hours

Effectiveness of the application

shortened the repairing cycle to 7 days, and increased the efficiency of the traditional process by 53%

increased the uniformity of the temperature of the furnace to ±15℃ (the original temperature was ±15℃) after the commissioning of the furnace. The temperature uniformity of the furnace was increased to ±15℃ (original ±35℃)

The life of the lining was extended to 18 months (original masonry structure averaged 12 months)

The annual maintenance cost was reduced by 2.2 million yuan, and the benefit of production increased by more than 5 million yuan

Customer Evaluation

The new castable solution makes the effective volume utilization rate of the blast furnace increased to 92%, and the thermal efficiency was increased by 15%, and it shows excellent anti-scaling performance especially in the response to fluctuations in furnace conditions, which provides a reliable guarantee for the continuous production. The furnace is a reliable guarantee for continuous production.

Supporting technology description

According to specific requirements, we can provide:

√ Material thermal expansion coefficient curve (20-1600℃)

√ Carburization resistance test report

√ Customized construction plan design

√ 24-hour remote technical guidance

Extended application in the industry

The castable technology has been successfully applied in:

◼ Cement rotary kiln transition zone (1400℃ cyclic heat load) ◼ Non-ferrous metal melting furnace slag line part (anti-Pb, Zn erosion)

◼ Waste incinerator second combustion chamber (Cl- corrosion resistant environment)

Get customized solution

Welcome to call or submit equipment parameters online, our refractory engineers will provide you with selection advice within 2 hours.